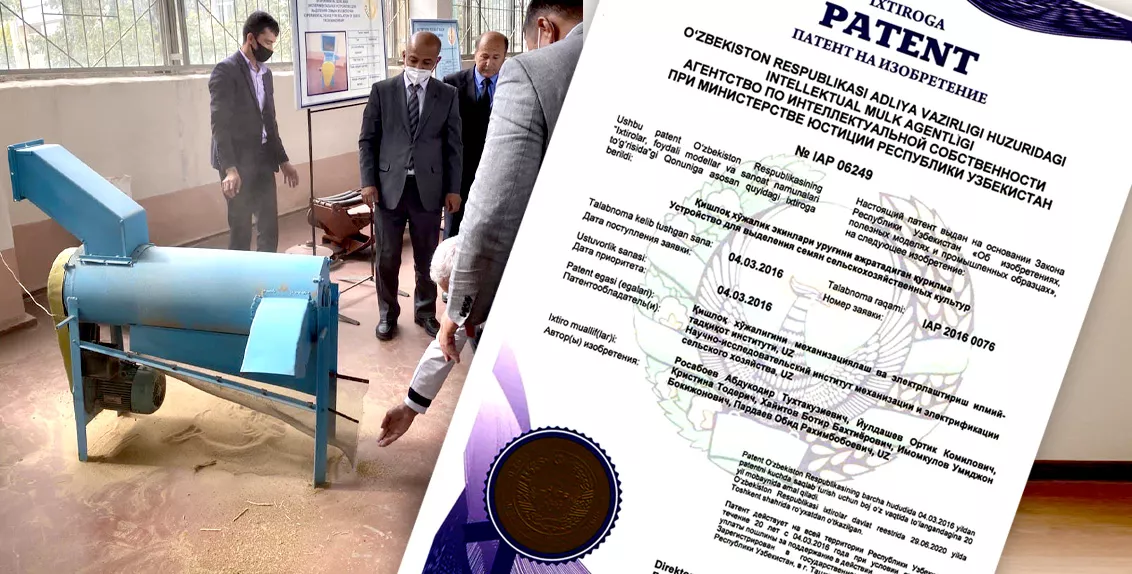

Scientists in Uzbekistan patent new quinoa seed processing machine

20 October 2020

Processing quinoa seed may soon become easier and cheaper thanks to a simple yet innovative machine developed by a group of inventors, including scientists from the International Center for Biosaline Agriculture (ICBA).

They recently obtained a patent for their invention from the Intellectual Property Agency at the Ministry of Justice of the Republic of Uzbekistan.

The machine was jointly designed and built by the Scientific Research Institute of Mechanization and Electrification of Agriculture; Tashkent State Agrarian University; and the International Center for Biosaline Agriculture (ICBA).

It can perform such functions as threshing, hulling, air cleaning, gravity separating, vibratory sieve separating and grading. It maximizes cleaning efficiency and minimizes wear and tear. It also runs on electricity and has the capacity of cleaning about 3-5 tonnes of seed per hour. More importantly, the machine can produce quinoa seeds that meet quality standards in terms of size and purity.

Quinoa is one of the most nutritious crops and has proven itself an excellent alternative with considerable biodiversity. It can adapt to different environments, including marginal ones that are most vulnerable to climate change, water scarcity and salinity.

As part of its global quinoa program, ICBA has been conducting research on quinoa since 2007. The center has identified and developed five genotypes suited to various agro-ecological conditions. Over the years, ICBA has introduced these genotypes in different countries, including Morocco, Egypt, India, Kyrgyzstan, Pakistan, Spain, Tajikistan, the United Arab Emirates, and Uzbekistan.

ICBA is now focusing on scaling up quinoa value chains in different regions, including Central Asia. One of the main challenges faced by farmers, particularly smallholders, is postharvest processing as they do not have necessary equipment for threshing, seed cleaning and other purposes. Therefore, most of the processing is done manually, which sometimes discourages farmers from growing such crops.

According to Dr. Aziz Karimov, Head of ICBA’s regional office for Central Asia and South Caucasus: “Over the past few years, quinoa production in Central Asia has been gradually growing. So has farmers’ interest in the crop. Production is expected to increase further in the coming years. Therefore, it would be important to replace traditional practices suitable for small-scale production with mechanized cultivation, harvesting and postharvest processing.”

For his part, Dr. Botir Khaitov, a post-doctoral fellow based at ICBA’s regional office, noted: “Since quinoa production is new to the Central Asian region, specific machinery has not been developed in the past to help resolve the technological challenges that hinder seed processing and the market for such technologies has been limited. Farmers are reluctant to cultivate a new crop for which there is no postharvest processing technology. We hope that this invention will facilitate the adoption and expansion of quinoa production in the region.”

Initially designed to clean quinoa seeds, the machine can also be used to clean seeds of other crops such as amaranth, alfalfa and other small-seed crops.

Dr. Botir Khaitov added that to help small-scale farmers in remote areas, the next step is to develop a mobile version of the machine which can run on solar power.

The machine was developed under the project titled “Cross-regional Partnerships for Improving Food and Nutritional Security in Marginal Environments of Central Asia”. Funded by the Islamic Development Bank (IsDB), the project was implemented by ICBA between 2013 and 2018.